Production Systems

Production Systems

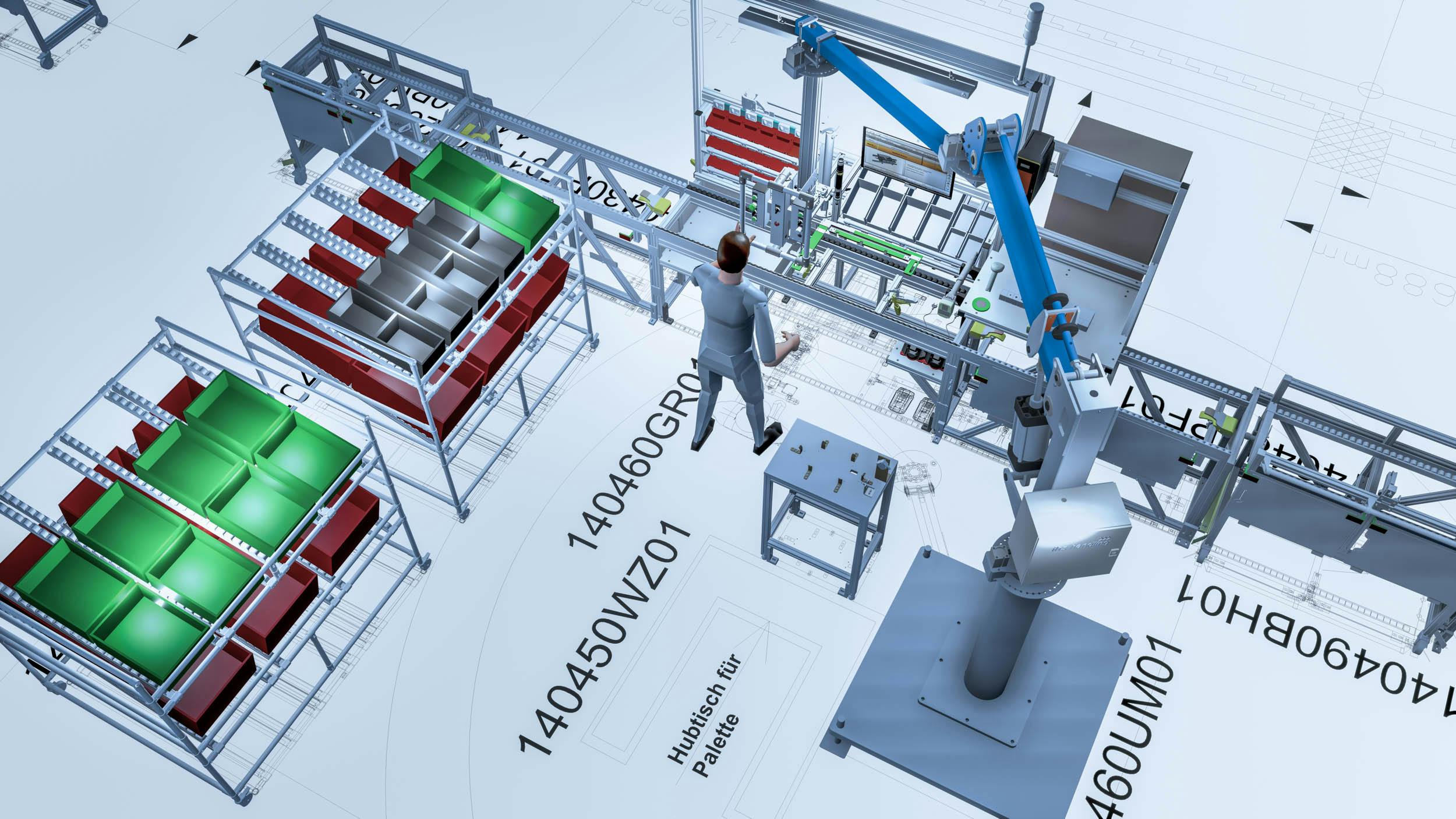

Customised system development: from idea to reality

Smart Factory

We design future-oriented assembly systems and customised special machines that support our customers on their way to the factory of the future. Our comprehensive approach includes holistic advice on optimising production technology - from product development and the selection of efficient manufacturing processes to the development of state-of-the-art production systems.

Product and process analysis

The first step is to analyze the entire assembly process and then plan the corresponding manufacturing steps and processes.

In the process, our engineers work with the customer team to develop optimization options for the mechanical manufacturability of the product. The aim of this collaboration is to achieve an optimal “cost-breakdown” of the manufacturing process.

Traceability and quality gates

We already include the product requirements for traceability and quality gates at the development stage of the production lines. For manual stations, we also develop and implement the worker assistance system with traceability with our team.

In preparation for traceability and quality gate planning, we recommend creating a Process FMEA. To make sure we tailor our response to individual customer requirements, we hold a joint workshop between our team and the customer to discuss the project in advance.

Virtual engineering on the assembly line

Our specialist team of qualified engineers can provide the complete solution for your production line through design, simulation and programming.

- 3D engineering, simulation and virtual 3D optimization of the assembly process

- Electrical design hardware

- Software design, data structure traceability, programming worker guidance

- Data interface for “paperless” production control to ERP (SAP) and MES systems

Assembly and operational handover

As we have worked in the engineering sector for many years, you can count on our extensive know-how and our exceptional customer experience. We take over

- The production and assembly of the assembly line for you with partner companies

- Commissioning of line control, robotics and assistance systems by Schulz Engineering staff and coordination of process system suppliers

- Operator and worker training

- Operational transfer of the assembly line to the SOP

Worker guidance and traceability

We implement worker guidance and traceability in the ELAM 4 platform system of our cooperation partner Armbruster Engineering.

The use of ELAM software, a so-called worker assistance system, creates agile and flexible assembly lines in which employees are supported by digital work instructions during assembly.