Robotics

Robotics

Engineering of the future

Optimized production processes

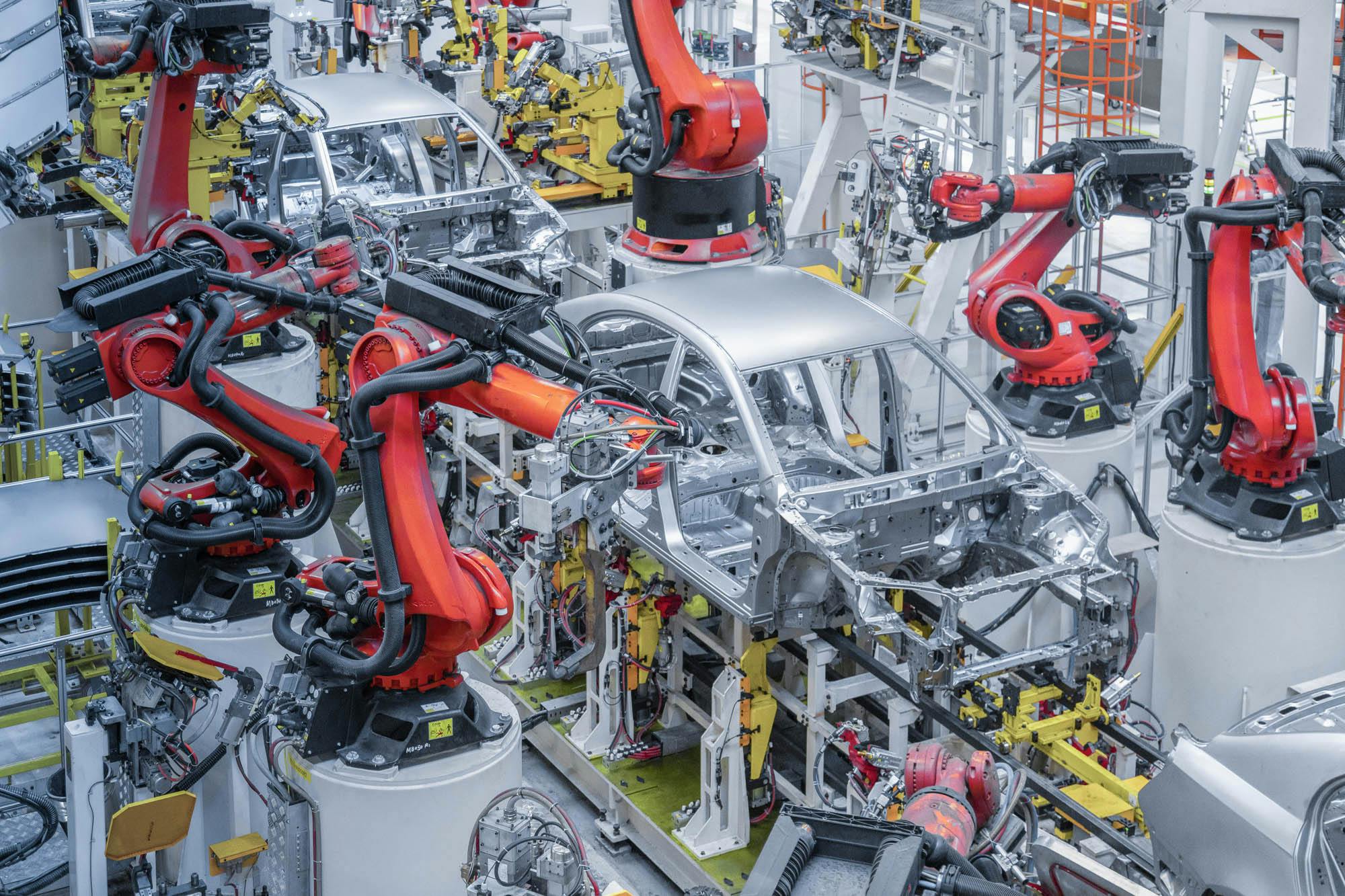

As experts in the field of robotics, we offer offline programming, online commissioning and start-up support.

We work with various well-known manufacturers to program the right robots for your requirements. Our top priorities are to implement your project with the highest quality standards and deliver it on time.

Our services

We determine optimal travel paths for you, create collision-free motion paths for all process, service, and secondary applications, and define robot and system interlocks.

We take over the calibration of the robots on site as well as the import of the generated OLP offline programs into the robots. We automate the robots with plant control and the process equipment. In this way, we ensure risk-free commissioning

With our on-site start-up support, you can also rely on us for any commissioning or optimization of your equipment. Because we are only satisfied when you are.

We are here for you

Contact us, we will be happy to advise you!

Further services

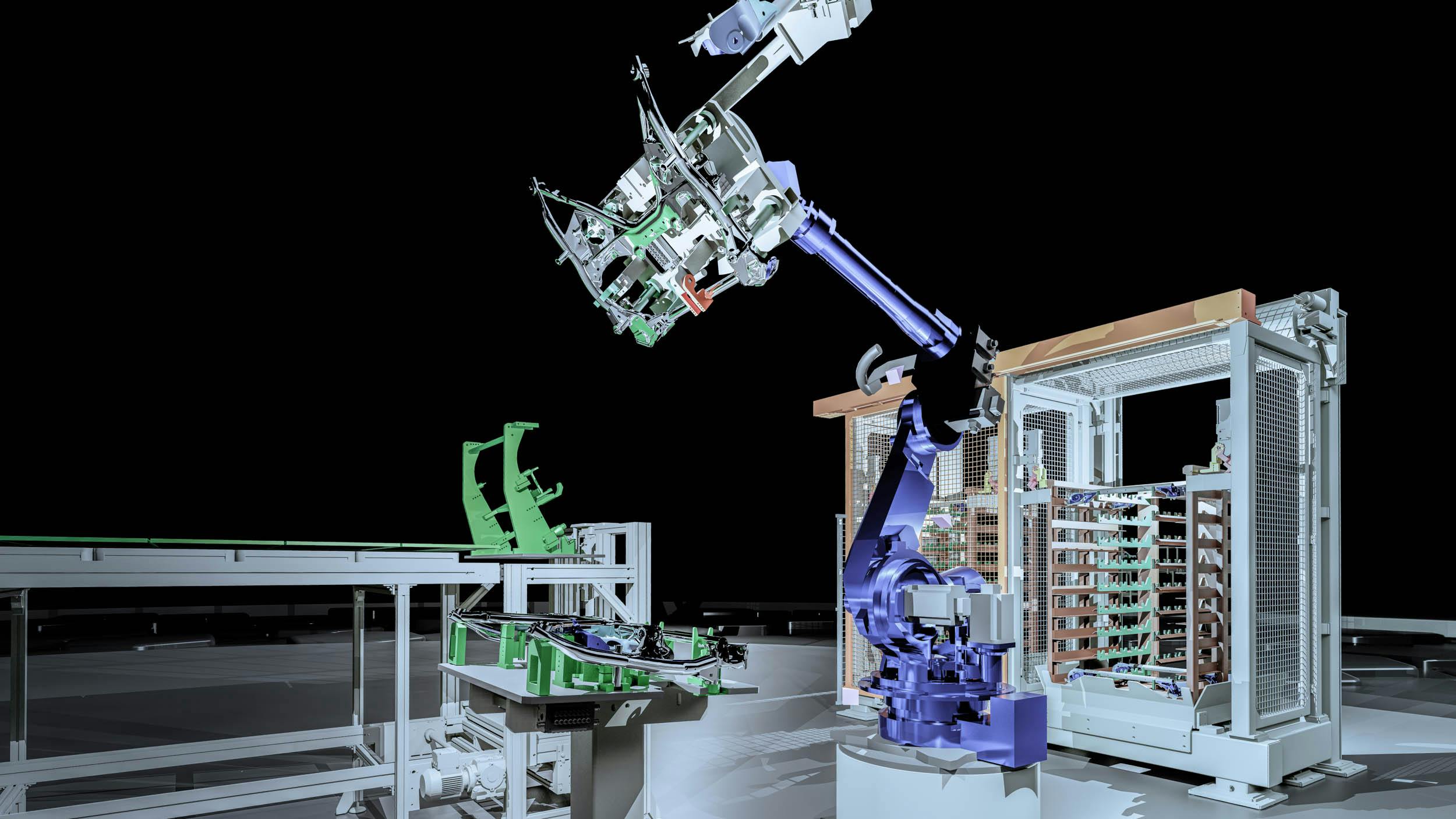

With our robot simulations, we create a virtual environment to ensure in advance that the processes, plant design and worker safety are all guaranteed. Thanks to our broad portfolio of services, we are able to back up the simulation with a hazard and risk analysis using a wide variety of systems, e.g. SafeExpert.

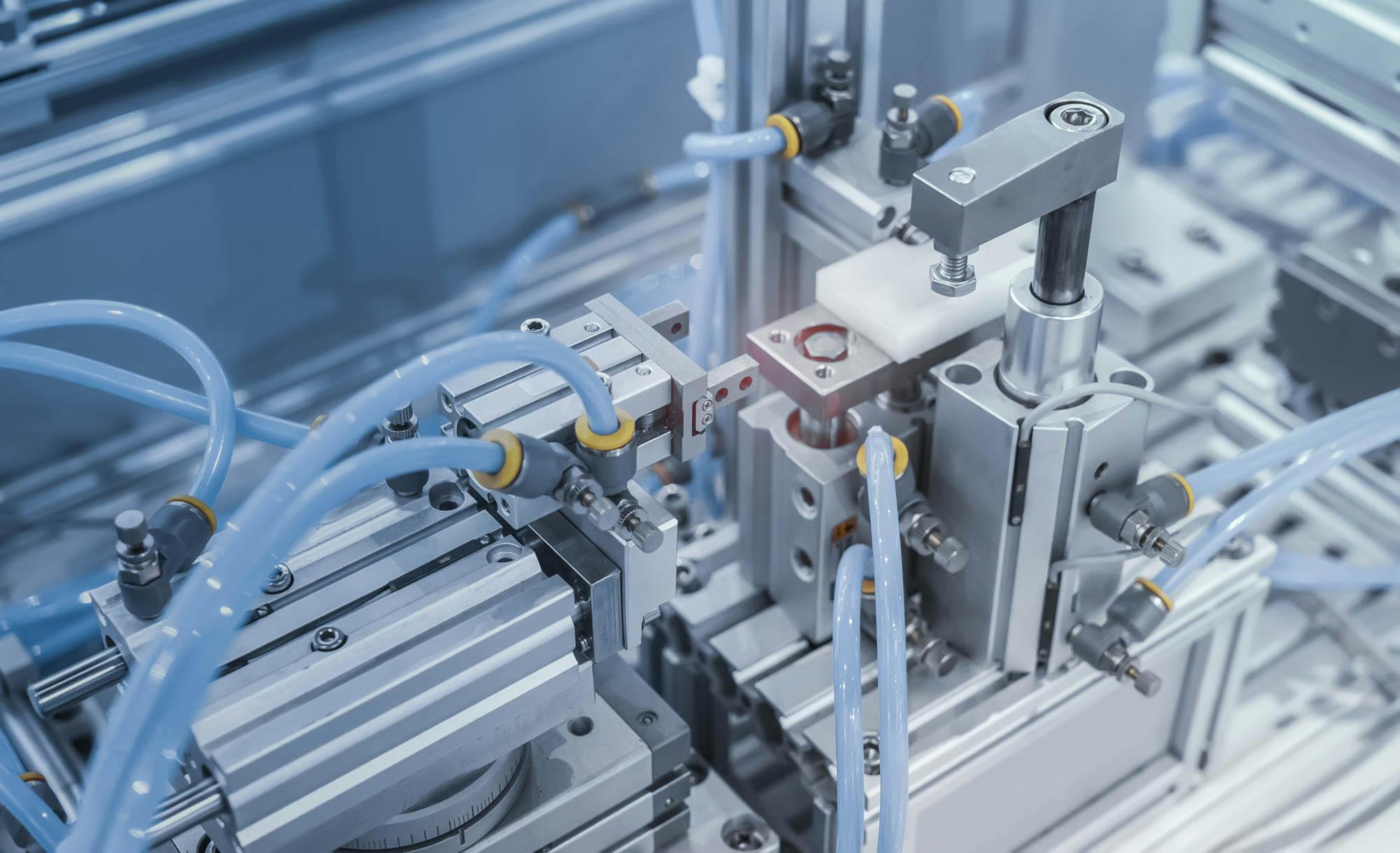

Electropneumatics is successfully used in many areas of industrial automation technology. The change in requirements and technical developments have significantly changed the appearance of the controls.

We are specialists in the design of special machinery and equipment in plant engineering. Our day-to-day operations not only include complete support for new constructions but also adapting and optimizing existing plants.