Planning

Planning

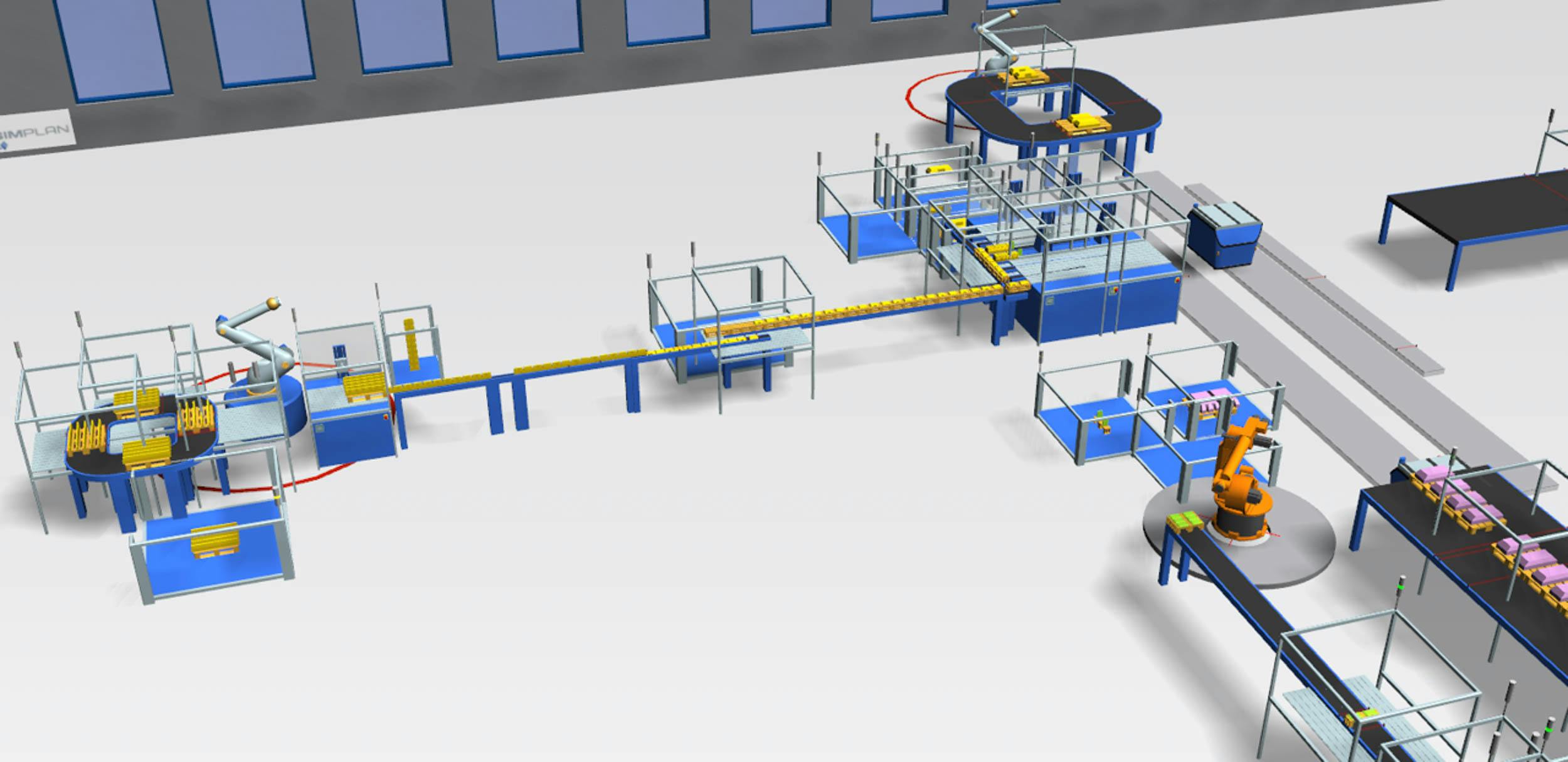

Digital factory planning

Extensive support for planning

Building on our experience and expertise gathered over many years, as well as our creativity, we can develop innovative plant concepts and system-optimized processes perfectly tailored to your needs. In doing so, we offer you comprehensive support throughout the entire duration of the project. From concept planning and detailed design to the finished 3D layout in the digital factory, you can always count on us for reliability.

We use state-of-the-art tools and methods of planning to ensure the feasibility of the projects in the development phase. Problematic geometries in the building and existing facilities are transferred to the digital factory model by 3D laser scans, thus ensuring the feasibility of the planning layout. The output of the production lines are validated through availability and yield simulations. In addition, we use Methods-Time Measurement to evaluate and subsequently optimize manual activities. Even during the concept phase, we consider plant and worker safety and evaluate them with hazard and risk analyses.

Put your production planning in first-class hands.

For more than 40 years, we have been implementing a wide variety of projects, from the development of a product to the on-site commissioning of complex production facilities.

We accompany our customers from the earliest planning and concept phase in order to provide them with support and advice. Our success is based on the process of simultaneous engineering, in which product technologies and production design are developed in parallel.

A considerable advantage for you here is the optimization and shortening of development and innovation times. With our combined expertise, we focus on efficiency and quality and work passionately and creatively on innovative solutions. Our team offers you an all-round carefree package.

We are engineers of the future. Here and now.

For decades, we have been implementing the planning of production lines using the Digital Factory concept.

In the process, we create a digital twin of the production line, which includes the real geometric dimensions and the requirements of the production processes. The line concepts are then mapped in virtual reality 3D simulation systems.

The line and process concepts are already secured in advance during the planning for production areas and logistics. In this way, we can offer you a complete solution tailored to your individual requirements, with an overview of costs and a schedule guarantee.

Our vision is the future-oriented and sustainable design and construction of your factory.

We are here for you

Contact us, we will be happy to advise you!

Further services

Our team of experts offers you an all-round package, starting with concept development, tendering and selection of suppliers right up to overall budget overview and on-site control of the project's timely implementation.

Material flow simulation allows you to react to events at an early stage, before the facts from reality are available. It can be applied in the deployment, feasibility, conceptual design and detailed design phases.

The 3D capture of complex environments in industry helps to optimize planning and construction processes. With laser scanners, we can capture even complex and difficult-to-access systems for you, if necessary even during ongoing operation.